The Revolutionary Potential of Diamante CVD in Modern Industry

Diamante CVD, also known as diamond Synthetic Fume Deposition (CVD), has arisen as a momentous innovation in various industries. This process enables the development of great synthetic diamonds, which have numerous applications across sectors like electronics, medication, and manufacturing. Diamante CVD innovation has made it possible to create diamonds that have the same optical, thermal, and mechanical properties as normal diamonds, however with more prominent precision and less environmental impacts.

What is Diamante CVD and How Does it Work?

Diamante CVD involves depositing carbon atoms onto a substrate to frame a dainty film of diamond. This is accomplished by establishing a controlled environment wherein carbon atoms bond together under specific temperature and pressure conditions. In the diamante CVD process, a gas, frequently methane or hydrogen, is warmed until the carbon atoms separate and connect themselves to a substrate, making a diamond layer.

Diamante CVD innovation has the special capacity to make diamonds with customizable shapes and properties. Not at all like conventional high-pressure, high-temperature methods, the CVD process is more energy-proficient, which has diminished creation costs and increase accessibility.

Applications of Diamante CVD in Electronics

The electronics industry has embraced diamante CVD for its impressive properties, especially in making semiconductors. Synthetic diamonds created by diamante CVD have excellent thermal conductivity, making them ideal for cooling systems in elite execution electronics. This is especially basic in high-power devices where heat dissipation is critical for keeping up with productivity and forestalling overheating.

Diamante CVD diamonds are also exceptionally resistant to radiation, which extends the life span of electronic components, especially in industries like aerospace and thermal power. The capacity of diamante CVD to create uniform, imperfection free lab made diamonds with high virtue has prompted advancements in transistors, microchips, and other superior execution components, working on the unwavering quality and execution of electronic devices.

Clinical Advancements Through Diamante CVD

In the clinical field, diamante CVD has changed the development of clinical tools and implants. The biocompatibility and sturdiness of CVD diamonds make them ideal for surgical blades, as they can hold sharpness longer than regular materials. Also, CVD diamonds are currently used in dental tools, laser equipment, and even in specific embed materials due to their non-responsive and hypoallergenic properties.

Diamante CVD also plays a job in imaging and diagnostics, where it enables greater imaging and decreased impedance. The novel properties of synthetic diamonds made through the diamante CVD process consider more prominent precision in clinical imaging tools, such as those used in X-ray or CT scans. By lessening signal noise and further developing resolution, diamante CVD-based innovation has opened additional opportunities in harmless diagnostics and upgraded patient consideration.

Diamante CVD in Manufacturing and Cutting Tools

Diamante CVD has gotten amazing advancements manufacturing and cutting tool applications. Synthetic diamonds delivered through the CVD process are known for their hardness and wear resistance, making them essential in tools used for cutting, crushing, and boring hard materials like metal, glass, and ceramics. Tools made with diamante CVD last longer as well as convey better exactness and precision, which is vital in industries such as automotive, aerospace, and construction.

The reception of diamante CVD in manufacturing has also added to greener creation methods. Diamante CVD-based tools require less incessant replacement and lower support costs, which translates into decreased waste and worked on functional proficiency. This sustainability factor, combined with the superior exhibition of diamante CVD, makes it an increasingly well known decision in current manufacturing.

Diamante CVD’s Job in Optical and Laser Systems

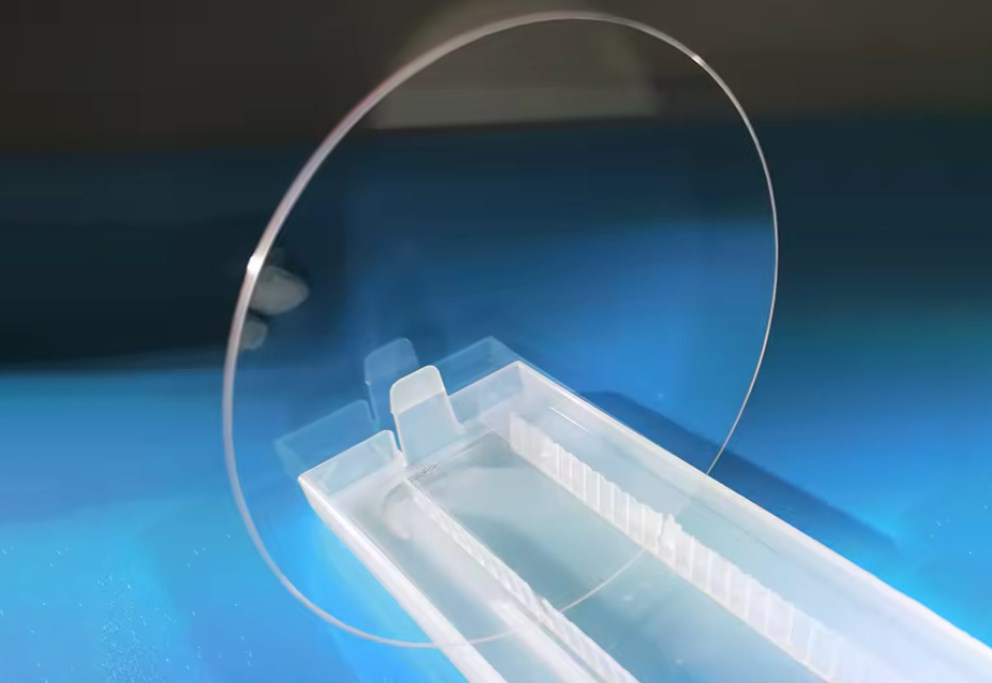

In optical and laser systems, the superior optical properties of diamante CVD diamonds are profoundly esteemed. These synthetic diamonds have a high refractive record and can handle intense laser beams without corruption. This is especially useful in industries that depend on high-precision lasers, such as telecommunications and defense.

Diamante CVD has empowered the production of excellent diamond lenses and windows for use in cutting edge optical instruments. The lucidity and sturdiness of CVD diamonds make them suitable for environments that require both superior execution and life span. Furthermore, these diamonds are resistant to corrosion and scratching, which increases the lifespan of optical components and lowers upkeep needs, thus giving a cost-successful solution.

Environmental and Financial Benefits of Diamante CVD

One of the critical advantages of diamante CVD is its lower environmental effect contrasted with conventional diamond mining. Synthetic diamonds made through CVD don’t add to the ethical and environmental concerns associated with mining, such as living space destruction and laborer abuse. By creating diamonds in a controlled environment, diamante CVD offers an eco-accommodating elective that minimizes mischief to the planet.

From a monetary standpoint, the increased availability of CVD diamonds has also determined down costs. Industries that once depended on expensive normal diamonds can now accomplish similar, in the event that not superior, execution for a portion of the cost with diamante CVD. This cost-effectiveness, joined with the great and versatility of CVD diamonds, has spurred development and advancement across various sectors, setting out new open doors and applications.

The Eventual fate of Diamante CVD Innovation

Looking forward, diamante CVD innovation is supposed to keep developing, opening considerably more possible applications. Advances in precision and productivity inside the CVD process may soon empower significantly more extensive use of synthetic diamonds in arising technologies like quantum registering and nanotechnology. As research progresses, diamante CVD could further work on in terms of energy productivity, scalability, and customization options, making it much more interesting to various industries.

Diamante CVD is also poised to assume a basic part in sustainable development, as additional industries focus on environmentally well disposed alternatives. Its contributions to both monetary development and environmental preservation make diamante CVD an important tool in building a sustainable future. With continuous development, diamante CVD will probably cement its place as a cornerstone innovation in a large number of fields.

Conclusion

Diamante CVD represents a mechanical jump that is reshaping industries around the world. With applications in electronics, medication, manufacturing, and more, the benefits of diamante CVD stretch out a long ways past customary diamond use. Its advantages in terms of solidness, precision, and eco-friendliness make diamante CVD an essential piece of present day industry, empowering more productive, cost-viable, and sustainable practices. As the demand for superior execution materials grows, diamante CVD will without a doubt assume an increasingly focal part in addressing those needs.